Nowadays, camera inspections are one of the standard procedures for inspecting and assessing structures in groundwater.

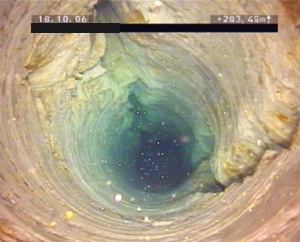

With our camera systems, we can examine vertical pipe strings and shafts, but also open boreholes in solid rock from 50 mm to approx. 1500 mm diameter, at a maximum examination depth of 400 m (maximum diameter depends on water turbidity).

The cameras used are swivel head systems with free axial and radial rotation and zoom lenses (10x). The videos are recorded in full colour and DVD resolution (MPEG2) and handed over to the client on DVD or USB stick.

In addition to the general examination of the pipe structure (pipe material, pipe connections, position and condition of the filter section), the camera inspection can be used to analyse different types of deposits, signs of corrosion, damaged areas and, taking into account other geophysical methods, chemical and biological precipitation products.

Based on these results, the hydraulic functionality of the structure can be assessed and, if necessary, an optimal rehabilitation or regeneration plan can be designed (old wells or measuring points).

For the repair/sealing of damaged areas, we offer the installation of stainless steel sealing collars for diameters of 100 - 1000 mm.

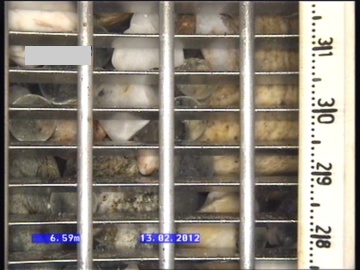

In addition to the general condition analysis, we also carry out an exact examination of the filter slot widths at the customer's request, regardless of the pipe material.

In stainless steel wound wire filters, a visual grain size analysis of the filter sand / gravel fill can also be carried out to ensure that the installed material corresponds to the construction plan. The grain size analysis after television sounding serves to precisely record the backfilling of the annular space near the filter. For this purpose, TV soundings are carried out at defined intervals, e.g. every 90°: north / east / south / west direction, in each of which a light plummet is used for size analysis.

A switchable laser measurement system also allows objects and cavities to be measured in terms of size and distance with limited visibility.

For the inspection of horizontal pipe strings (from 300 mm diameter), a specially developed camera trolley is available.

This also allows a complete inspection in axial and radial alignment.

The maximum length for the inspection of horizontal pipe strings is 400 m.

For camera inspections with special boundary conditions, our systems can be adapted to almost all measuring environments through technical conversions.

If you have any questions, please contact us directly so that we can work out specific implementation concepts together with you.